Developed by Dr. W. Edwards Deming and rooted in quality management principles, the PDCA technique equips organizations with a practical framework for continuous improvement. We’ll explore the PDCA cycle’s structure, benefits, practical applications, and common challenges.

What is the PDCA Cycle?

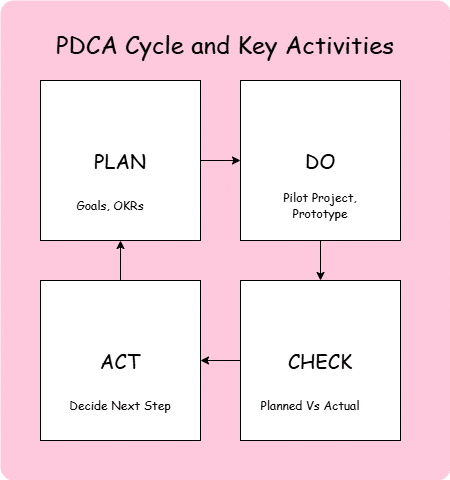

The PDCA cycle is a four-step iterative process designed to drive continuous improvement. Each phase builds on the previous one, ensuring data-informed decisions and sustainable outcomes.

Plan

The planning phase involves:

- Identifying the problem or improvement opportunity.

- Analyzing current conditions and defining objectives.

- Designing potential solutions with a focus on feasibility.

Tools like the SWOT analysis, flowcharts, and brainstorming sessions are instrumental in crafting a solid plan.

The Plan phase begins with identifying a need or opportunity for improvement, often triggered by persistent problems, inefficiencies, customer feedback, or changes in market conditions. Recognizing the right problem or opportunity is crucial, as addressing the wrong issue wastes resources.

Root Cause Analysis

To ensure this phase is thorough, organizations can conduct root cause analysis using tools like the Fishbone Diagram or the “5 Whys” method, which helps trace issues back to their origins. Effective brainstorming sessions are also key and can be driven by fostering an open, judgment-free environment where all ideas are welcomed. Facilitators should guide discussions with clear objectives, ensuring the focus remains on actionable insights rather than unrelated problems. This preparation lays the groundwork for a robust plan with achievable goals. This phase concludes with setting goals and metrics for measurement.

2. Do

Here, the focus shifts to implementation:

- Execute the plan on a small scale to minimize risks.

- Gather data on performance and outcomes.

- Engage stakeholders for feedback and fine-tuning.

Pilot projects and prototypes are commonly used to test ideas without committing significant resources. Running a good pilot project starts with defining its scope and objectives—keeping it manageable while ensuring it reflects real-world conditions. In software development, high-fidelity prototypes are used to collect feedback from users before full development. Regardless of the technique used, engaging stakeholders throughout the process is important. For example, at the start, explain the purpose of the pilot or prototype and how their input will shape the final solution.

Check

This phase evaluates results:

- Compare actual outcomes with expected results.

- Use performance metrics and analytical tools to identify gaps or successes.

- Document findings to guide future iterations.

Key performance indicators (KPIs) and control charts are often employed for effective monitoring.

The insights gained in the Check phase directly inform the next step, the Act phase. If the results show that the objectives were met, the new processes can be standardized and integrated into regular operations. If there are gaps, the findings help refine the plan or identify additional actions needed to achieve the desired outcomes.

Act

In the final phase:

- Implement successful strategies on a larger scale.

- Incorporate lessons learned into the process.

- Establish systems to monitor the refined process continuously.

The Act phase reinforces the cycle’s iterative nature, fostering ongoing improvement. Based on the insights gained during the “Check” phase, this is where you put the improvements into action, which could be any of the following:

- Implementing new solutions: Introducing new methods, technologies, or systems.

- Training employees: Providing necessary skills and knowledge to support the changes.

- Making adjustments: Fine-tuning the implemented changes based on initial results.

- Updating Work Processes: Updating standard operating procedures to reflect successful changes and training employees.

The Act phase doesn’t necessarily end the cycle. Instead, it marks the beginning of a new cycle.

Benefits of Using the PDCA Cycle

- Incremental Progress: Reduces the risk of large-scale failure by testing changes gradually.

- Data-Driven Decisions: Encourages using evidence to shape solutions.

- Enhanced Quality: Ensures processes align with organizational goals and customer expectations.

- Promotes accountability, collaboration, and a mindset of continuous learning.

The PDCA cycle has broad applications across industries including

Manufacturing:

Improving production lines, reducing defects, and optimizing resource utilization.

Healthcare:

Enhancing patient care protocols, minimizing errors, and streamlining operations.

IT and Software Development:

Managing agile workflows, debugging software, and refining user experiences.

Common Challenges and How to Overcome Them

Despite its simplicity, implementing PDCA can present challenges. The key issues are resistance to change and poorly defined goals.

Resistance to Change:

One of the key issues you’d encounter whenever you present the PDCA as a tactic for continuous improvement is resistance. And it happens due to several reasons.

- Employees may worry about job security, new skill requirements, or the potential for failure.

- Changes can disrupt routines, making people feel less in control.

- Employees may not trust leadership’s intentions.

- Poorly communicated changes can lead to confusion, anxiety, and a sense of being left out

There are several ways to mitigate this:

- Include employees in the planning and decision-making processes. This fosters a sense of ownership and buy-in

- Actively solicit and consider employee feedback and concerns throughout the process.

- Ensure everyone understands the changes, their roles, and the timeline for implementation.

- Actively listen to employee concerns and address them fairly and effectively.

Poorly Defined Goals

Poorly defined goals or Key Performance Indicators (KPIs) in the Plan phase of the PDCA cycle can derail the entire improvement effort.

Firstly, ensure a shared understanding of the problem or opportunity. Involve all relevant stakeholders in identifying and defining the issue.

Secondly, use a structured approach to goal setting; such as the SMART framework. For example, instead of a vague goal like “improve customer satisfaction,” a SMART goal would be “increase customer satisfaction scores by 10% within the next quarter by implementing a new customer feedback system and addressing the top three customer complaints.”

Thirdly, clearly define KPIs that directly measure progress towards the goals. For instance, instead of “improve employee morale,” a relevant KPI would be “reduce employee turnover rate by 5% within six months.”

Olutobi

I write about business and project management.

10+ years working in program management. I've worked in health-tech, community health, regulatory affairs and quality assurance.